How to make a garden chair with your own hands? How to make a wooden dacha chair with your own hands - instructions How to make a comfortable dacha chair.

» From the material presented, you will learn how you can make a "Garden Chair" with your own hands and install it on your site, for example, in the shade of a fruit tree (apple tree). On an armchair, rest after work on the beds will be much more convenient and pleasant, because due to the inclined back, the load is removed from the spine.

To make a chair, you do not need serious knowledge in carpentry and carpentry, everything is extremely simple and practical. The material is also the simplest - a board of 25-30 mm and screws.

Let's look at the whole process of creating the "Garden Chair", as well as analyze what exactly the author needed?

Material

1. board 25-30 mm (softwood)

2. screws (for wood)

3. stain

4. varnish

Instruments

1. hacksaw

2. screwdriver or screwdriver

3. ruler and pencil

4. brush

5. sandpaper

The process of creating a "Garden chair" with your own hands.

It is not so difficult to get your own country furniture, especially if you have material (pallets or a board), the planks must first be planed and sanded with sandpaper, and then just follow the author's photo instructions.

First of all, armrests are made from the board (in the form of the letter P), everything is twisted with the help of wood screws.

The rear legs are screwed at an angle to the front.

A seat is sewn onto the plane of the rear legs from the same board, a cross member is also added to strengthen the structure and greater rigidity.

The back is made in the same way, the boards are screwed to the lower and upper crossbars.

To give garden furniture of a more noble appearance, it can be covered with stain and varnish, or painted with paint in any color of your choice)

As you can see, there is nothing complicated in creating a garden chair, everything is extremely simple and clear.

So, do not throw away pallets and planks after construction or repair, they can be used to make cool furniture.

This concludes the article. Thanks for attention!

Come visit more often. Don't miss the news in the world of crafts!

The article is presented for informational purposes only!

In the considered version of making the Adirondack chair with your own hands, the design features are preserved, but there are no difficult carpentry joints. It will not be difficult to repeat the project by making wooden parts according to our drawings and assembling the product with screws.

The work uses a planed 20 mm pine board, galvanized screws 4.5x40 mm, bolts 10x60 mm with a square headrest and nuts with washers. An electric jigsaw and a grinder will speed up the process, and a manual milling cutter will allow you to carefully round the edges, but all workpieces can be cut with a regular hacksaw, and the burrs can be removed manually with sandpaper.

Adirondack chair device: 1 - backrest bar; 2 - screws; 3 - upper cross member; 4 - back leg; 5 — side support (spar); 6 - bolts; 7 - armrest; 8 - front leg; 9 - seat bar; 10 - armrest support

Adirondack chair device: 1 - backrest bar; 2 - screws; 3 - upper cross member; 4 - back leg; 5 — side support (spar); 6 - bolts; 7 - armrest; 8 - front leg; 9 - seat bar; 10 - armrest support

Parts manufacturing

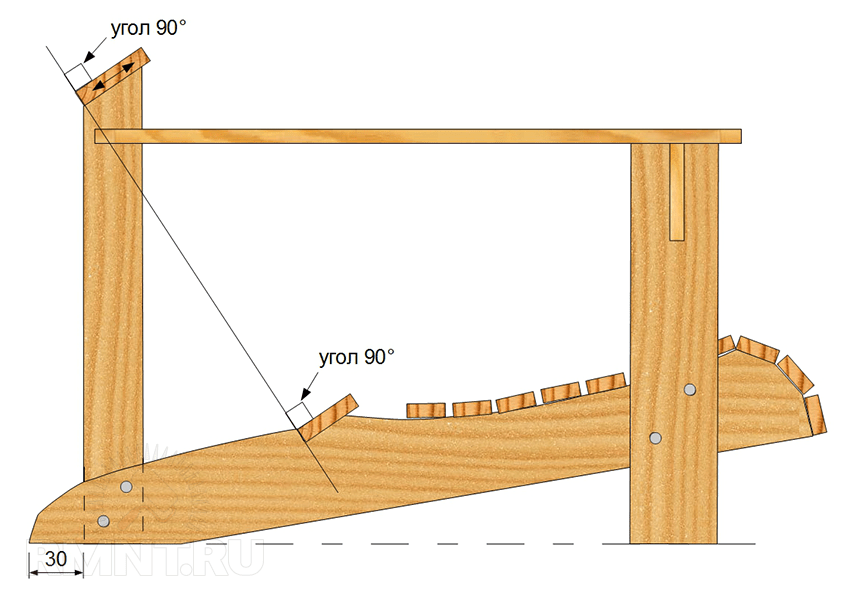

The most complex elements of the chair are the two side supports of the seat. Make a full size template for the spars on paper.

Side support drawing

Side support drawing

Draw the bottom side of the part, raise the first perpendicular segment on the left and two more at appropriate angles to point A. Mark point C and draw a cutout for the transverse tie as shown in the diagram.

Mark an angle of 75° with vertex C, extend its underside with a line. Draw an arc with a radius of 116 mm, measure the angle at point D and connect them with a line segment.

Draw a rounding between points A and B using a square grid or an impromptu pattern as in the photo.

Place the cut template on the board, avoiding large knots and leaving small knots away from the edges of the blanks. Circle the contours and file the details using a saw on straight sections, and cut out curly contours with a jigsaw. Guide the tool blade in the direction of the grain so that the wood is less chipped.

Transfer the drawings of the remaining elements of the chair to the boards, also using a template, or draw directly on the blanks and mark the next identical part according to the first cut out.

Detail drawings: 1 - upper backrest guide; 2 - lower cross member of the back; 3 - armrest (2 pcs.); 4 - armrest stop (2 pcs.)

Detail drawings: 1 - upper backrest guide; 2 - lower cross member of the back; 3 - armrest (2 pcs.); 4 - armrest stop (2 pcs.)

The shape of the rounding of the armrests is not structurally important, they can be drawn by hand or according to the pattern. Mark the second part in a mirror so that the chips when sawing are at the bottom of the workpiece.

Detail drawing: 1 - backrest bar (7 pcs.); 2 - seat bar (8 pcs.); 3 - front leg (2 pcs.) 4 - back leg (2 pcs.)

Detail drawing: 1 - backrest bar (7 pcs.); 2 - seat bar (8 pcs.); 3 - front leg (2 pcs.) 4 - back leg (2 pcs.)

Sand the ends, connecting the same workpieces together if possible. Roughen the edges of the upper surfaces of the armrests and backrest slats, or simply soften the sharp edges with a grinder.

Chair assembly

Wooden furniture always begins to rot from joints, the inner surfaces of which cannot be processed on a finished chair. Therefore, cover the parts before assembly with 2-3 layers of antiseptic.

Most of the components of the chair are connected with screws, the pilot holes for them are drilled with a combined countersink, matched to the thickness of the screws. When they want to hide the hats, they are deepened and closed with plugs for glue.

Put an unnecessary board on the table, and place the left side support and front leg on top. Align the workpieces according to the drawing, mark the drilling points.

Assembly diagram of the side of the chair

Assembly diagram of the side of the chair

Make holes for the bolts and fasten the parts. Install the rear leg, placing it perpendicular to the bevel of the support. Assemble in the same way right side frame. Connect the sides of the chair with the lower backrest bar and the first seat bar.

Install supports on the front legs, fixing them with clamps for convenience. Attach the armrests with screws.

Attach the upper backrest rail, aligning it with the lower crossbar. Right now it is possible to correct possible inaccuracies of marking and uneven cuts that have accumulated by a millimeter.

Small errors are eliminated by shifting the upper crossbar and trimming the corner under it. In extreme cases, you will have to unscrew the lower crossbar and adjust the cutout.

Mark the center lines on the cross planks and on the center backrest. Holding the latter at the top with your hand or grabbing it with a clamp, drill a pilot hole and wrap the bottom screw. Check the vertical position and secure the top of the rail.

Screw in turn all the strips with a uniform interval. Take a string and tie one end to a pencil and the other to a nail fixed at the junction of the seat and back. Draw a radius of curvature, cut the strips according to the markup and sand the edges.

After adjusting the width of the last seat rail, put it in place. look around assembled chair and sand the marking marks, chips and other defects. Carefully sand the top surfaces of the back and seat parts.

Finish the wood with an oil impregnation if you want to preserve the natural shade. Use a synthetic resin glaze to create an opaque colored surface.

6732 1 2

How to make a garden chair: drawing and detailed description assembly

Have you decided to buy a plastic chair or a wicker rattan lounger for your summer cottage? Do not rush to spend money, because simple and at the same time comfortable furniture can be made of wood with your own hands. I propose a simple step by step instructions self assembly armchairs from wooden planks. But first, let's decide what kind of furniture you would like to see in your summer cottage.

Requirements for country wooden furniture

In order to decide what kind of country chairs should be, let's imagine in what conditions and for what purpose this furniture is used.

The country chair is a design with a seat, a back and armrests. If skids are attached to the supports, it will be possible to swing on the chair. Country chairs are used for a short rest, both in the country house, and near it.

The operating conditions can be described as difficult, since most of the time the furniture is used outdoors.

So, what qualities should distinguish country furniture?

- Durability. Furniture should last as long as possible, despite precipitation, direct sunlight and other environmental factors.

- Simplicity and convenience of operation. Furniture should be easy to carry so that if necessary, it can be taken out of the house and then brought back. Ideally, furniture should be laid out at all.

- low cost. The chair should be inexpensive, and preferably generally made with your own hands from available materials.

- Aesthetic appeal. The chair, which will be used in the country, should decorate the interior and exterior with its appearance. country house.

How to prepare for work

First, select a drawing. If furniture is being made for the first time, the simpler the drawing, the better. In our case, the drawing is simple, but the finished furniture will be beautiful, stable and durable.

After the drawing is ready, we count the amount of materials and purchase everything you need. In our case, a board with a section of 30 × 150 mm will be used to assemble the frame. For lining the seat and back, we use a board with a section of 25 × 100 mm. Wood screws 40 mm long will be used as fasteners.

Preliminary stage - cutting the main elements

In accordance with the drawing, we calculate the complete set of structural elements and cut them from the board required amount details. For longitudinal and transverse cutting we use a circular saw. For a curved cut, we use an electric jigsaw.

After cutting along the cut line, small chips or, on the contrary, protruding fibers will be noticeable. In order not to remove these defects on the finished furniture upon completion of the assembly, immediately after cutting, go along the edge of the cut with sandpaper.

Manufacturing process

| Illustrations | Assembly step by step |

|

How to screw in a screw? Almost all connections in the chair will be made using self-tapping screws, so you need to know how to screw them in correctly. Fastening of self-tapping screws is carried out with preliminary drilling of holes with a diameter of 2 mm. If you turn the self-tapping screw without pre-drilling holes, there is a risk of cracks. Under the head of the self-tapping screw, we drill a pot on the diameter of the head and a depth of 3 mm. The self-tapping screw is sunk into the recess below the surface of the board. |

|

front legs. We make two parts shown in the diagram. The lower part of the part will be the front leg of the chair, and a crossbar will be attached to the central recess. The top part of the part will be the armrest holder. |

|

We combine the front supports into a single knot. In the central recesses on the front supports, we install a transverse crossbar 70 cm long. All connections are made with carpentry glue and reinforced with self-tapping screws, 2 pieces on each side of the crossbar. |

|

Attaching armrest holders. We attach the upper parts of the sidewalls 60 cm long to the front supports. We maintain a right angle between these two parts. Fastening is carried out on carpentry glue and on 4 self-tapping screws for each connection. |

|

rear legs. From the board we cut two parts, like those shown in the diagram. The length of the legs is 63 cm. The end of the legs is cut at an angle of 75° and 115° respectively. |

|

Rear leg attachment. We apply the rear supports outside the armrest holders so that the cut line coincides with their surface. The extreme point of the lower part of the rear legs should be flush with the rear edge of the armrest holder. |

|

Strengthening the rear legs. So that during operation the rear supports do not move apart to the sides, we install a transverse strut between them and tighten the entire assembly with self-tapping screws, 2 pieces on each side. |

|

seat holder. The seat upholstery will be attached to the horizontal brackets. The horizontal holders will be fixed with a straight edge to the front cross brace, and with a beveled end - to the previously installed rear cross brace. |

|

How to install seat holders. The diagram shows the location of the three seat holders and their distance from each other. Fastening of parts, as usual, is carried out with self-tapping screws. |

|

Back and rear legs. Pieces of the board 61 cm long are attached to the outer holders of the seat. The fastening must be done so that the end of the backrest holder is flush with the lower edge of the seat holders. |

|

Back upholstery. On top of the previously installed backrest holders, we fill the strips with a gap of 20 mm between adjacent boards. |

|

Seat. The seat slats are attached in the same way as the backrest slats. |

|

armrests. Pieces of the board 64 cm long are attached to the sidewalls, as shown in the diagram. Fastening is carried out using carpentry glue and self-tapping screws. We use at least 2-3 self-tapping screws for each armrest. The edges of the armrests in front of the chair are rounded. |

We continue to work

After the assembly is completed and the chair is ready, it remains to complete Finishing work, as a result of which the furniture will become not only reliable, but also beautiful.

Since the assembly was carried out on self-tapping screws, recesses made under their heads remained on the surface of the tree. We fill the recesses with wood putty, matched to the tone of the boards. Putty is applied with a spatula and immediately leveled.

When working with putty, remember that such compounds are applied with a layer no thicker than 1-2 mm.

After the putty has completely dried, the wood surface is carefully sanded. For grinding, we use a grinder with replaceable skins. We use sandpaper variably, changing the abrasiveness from 400 to 800.

After the chair is sanded, we clean it of dust and impregnate it with drying oil in two layers with a break for the previous layer to dry. Impregnation is needed, firstly, in order to reduce paint consumption and secondly, in order to make the tree more resistant to decay. After the drying oil has completely dried, we apply a couple of layers of paint.

Can varnish be used? Since putty was used when working with lumber, spots will show through the varnish, therefore, in our case, the use of a continuous layer of paint is preferable.

The photo shows the finished result, which will look exactly the same if all the listed assembly steps were performed correctly in the order in which they are given in the instructions.

Summing up

Comfortable chair for a country house or suburban area It is not difficult to assemble at all and now you will definitely cope with this task. If you have any questions when assembling furniture, ask them in the comments to the article.

November 10, 2018If you want to express gratitude, add a clarification or objection, ask the author something - add a comment or say thanks!

In the considered version of making the Adirondack chair with your own hands, the design features are preserved, but there are no difficult carpentry joints. It will not be difficult to repeat the project by making wooden parts according to our drawings and assembling the product with screws.

The work uses a planed 20 mm pine board, galvanized screws 4.5x40 mm, bolts 10x60 mm with a square headrest and nuts with washers. An electric jigsaw and a grinder will speed up the process, and a manual milling cutter will allow you to carefully round the edges, but all workpieces can be cut with a regular hacksaw, and the burrs can be removed manually with sandpaper.

Adirondack chair device: 1 - back strap; 2 - screws; 3 - upper cross member; 4 - back leg; 5 — side support (spar); 6 - bolts; 7 - armrest; 8 - front leg; 9 - seat bar; 10 - armrest support

Parts manufacturing

The most complex elements of the chair are the two side supports of the seat. Make a full size template for the spars on paper.

Side support drawing

Draw the bottom side of the part, raise the first perpendicular segment on the left and two more at appropriate angles to point A. Mark point C and draw a cutout for the transverse tie as shown in the diagram.

Mark an angle of 75° with vertex C, extend its underside with a line. Draw an arc with a radius of 116 mm, measure the angle at point D and connect them with a line segment.

Draw a rounding between points A and B using a square grid or an impromptu pattern as in the photo.

Place the cut template on the board, avoiding large knots and leaving small knots away from the edges of the blanks. Circle the contours and file the details using a saw on straight sections, and cut out curly contours with a jigsaw. Guide the tool blade in the direction of the grain so that the wood is less chipped.

Detail drawings: 1 - upper backrest guide; 2 - lower cross member of the back; 3 - armrest (2 pcs.); 4 - armrest stop (2 pcs.)

Detail drawing: 1 - back strap (7 pcs.); 2 - seat bar (8 pcs.); 3 - front leg (2 pcs.) 4 - back leg (2 pcs.)

Transfer the drawings of the remaining elements of the chair to the boards, also using a template, or draw directly on the blanks and mark the next identical part according to the first cut out.

The shape of the rounding of the armrests is not structurally important, they can be drawn by hand or according to the pattern. Mark the second part in a mirror so that the chips when sawing are at the bottom of the workpiece.

Sand the ends, connecting the same workpieces together if possible. Roughen the edges of the upper surfaces of the armrests and backrest slats, or simply soften the sharp edges with a grinder.

Chair assembly

Wooden furniture always begins to rot from joints, the inner surfaces of which cannot be processed on a finished chair. Therefore, cover the parts before assembly with 2-3 layers of antiseptic.

Most of the components of the chair are connected with screws, the pilot holes for them are drilled with a combined countersink, matched to the thickness of the screws. When they want to hide the hats, they are deepened and closed with plugs for glue.

Put an unnecessary board on the table, and place the left side support and front leg on top. Align the workpieces according to the drawing, mark the drilling points.

Assembly diagram of the side of the chair

Make holes for the bolts and fasten the parts. Install the rear leg, placing it perpendicular to the bevel of the support. Assemble the right side of the frame in the same way. Connect the sides of the chair with the lower backrest bar and the first seat bar.

Install supports on the front legs, fixing them with clamps for convenience. Attach the armrests with screws.

Attach the upper backrest rail, aligning it with the lower crossbar. Right now it is possible to correct possible inaccuracies of marking and uneven cuts that have accumulated by a millimeter.

Small errors are eliminated by shifting the upper crossbar and trimming the corner under it. In extreme cases, you will have to unscrew the lower crossbar and adjust the cutout.

Mark the center lines on the cross planks and on the center backrest. Holding the latter at the top with your hand or grabbing it with a clamp, drill a pilot hole and wrap the bottom screw. Check the vertical position and secure the top of the rail.

Screw in turn all the strips with a uniform interval. Take a string and tie one end to a pencil and the other to a nail fixed at the junction of the seat and back. Draw a radius of curvature, cut the strips according to the markup and sand the edges.

After adjusting the width of the last seat rail, put it in place. Inspect the assembled chair and sand the marking marks, chips and other defects. Carefully sand the top surfaces of the back and seat parts.

Coat the wood oil impregnated if you want to keep the natural shade. Use a synthetic resin glaze to create an opaque colored surface.

All photos from the article

The cost of massive furniture is quite high, because many owners country houses and dachas make wooden chairs with their own hands. Having at hand a modern tool and a charge of healthy enthusiasm, any man will cope with this task without any problems. We'll show you how to build wooden chair to give their own hands.

Armchair for summer cottage made of wood

Peculiarities

Wood - best material for making furniture. Despite a number of shortcomings that this material has, we have nothing better.

We chose wood for a whole range of qualities that, in our opinion, are ideal for do-it-yourself work in a summer cottage:

- Wood raw materials are very malleable for processing with primitive tools: drilling, punching with nails and self-tapping screws, grinding, milling, etc. We have to do manual work simple means, so this moment is extremely important;

- Lumber is available almost anywhere in our country. Board and timber are widely represented on store shelves, and their price is relatively low;

- The material is completely natural and does not contain harmful impurities, does not emit toxins and volatile toxic chemicals;

- Boards and beams emit a pleasant smell, and coniferous parts do this especially actively;

- The texture and color of the surfaces are distinguished by their unique beauty, which is the best suited for the countryside atmosphere.

Important!

The listed set of qualities makes wood the most suitable material for the manufacture of a country chair.

It should be remembered that the product will be operated in conditions close to extreme. It will be exposed to rain, the sun will shine on it, it will be surrounded by insects, bacteria and fungal spores. Therefore, special attention should be paid to the choice of breed, finishing and processing of parts with an antiseptic.

The most suitable species in our case are oak, beech, ash, larch and pine. For parts that will not experience increased loads, you can use linden or alder.

Important!

All wooden parts must be impregnated with an antiseptic complex, and then painted or varnished.

Model selection

There are so many possible options for choosing a chair model that we see no reason to consider them in detail within the framework of the article.

It can be:

- folding and stationary models;

- rocking chairs;

- single and double;

- children and adults;

- high and low structures.

We will just give a few tips.

You must keep in mind two basic rules:

- Choose those models whose design is completely clear to you. You must imagine in advance what and how you will do, what tools to work with and whether you can master this or that detail;

- Consider the features of the place where the item will be used. A rocking chair or a folding model is perfect for giving, by the way, you can find drawings of a wooden folding chair with your own hands on our website.

Important!

Choose simple and reliable models that you can definitely make.

Consider the features of their operation.

Chair making

So, we will make the model presented in the photo at the beginning of the section. It consists of two sides, three sides and 35 cross rails that will form the seating surface.

The hardest part is cutting out the sidewalls. We will present a cutting on a metric grid with a step of 100 mm, according to which you can make a template and transfer the drawing to a sheet, from which you can then cut it out.