Barbecue from a small gas cylinder. How to make a grill from a gas cylinder with your own hands? Brazier smokehouse from gas cylinders: video

It is difficult to imagine a vacation in the country without barbecue or grill. The modern market offers a variety of braziers of different designs. However, it is not necessary to buy a brazier - it is not difficult to make such a device yourself. One of the options homemade stoves for cooking meat - barbecue from a gas cylinder.

It is practical, convenient, can have a different appearance - for example, the shape of a steam locomotive - and will be a great addition to summer cottage. How to make such a brazier, we will consider in this material.

We make a brazier from a metal cylinder

First you need to decide whether the creation of a brazier from such a container will the best option. Still, it is possible from almost any materials at hand: potbelly stoves, barrels, sheets of unnecessary metal, bricks - there are a lot of options.

Gallery of ready-made options

Advantages

The first and main advantage that distinguishes home-made barbecues is cost-effectiveness compared to purchased ready-made barbecues. Even if the old gas cylinder was not found on the farm, you can purchase such a container at a low price. It remains only to properly prepare it for turning into a brazier.

Other advantages of a brazier from a cylinder include:

It is worth noting the dimensions of the structure: you can cook twice as much meat on a barbecue grill from a cylinder than on a cheap purchased metal barbecue.

Users often search:

disadvantages

The disadvantages of using such a product include:

- Unsightly appearance of a standard cylinder, especially if it is old. Peeling red paint, dents and weld marks will spoil the aesthetics of a barbecue if you do not work on its finish. It is better to use a heat-resistant coating - this will additionally protect against burns when cooking.

- A large mass of construction - such a brazier will be portable only conditionally. It will definitely not work to take the product with you to nature, so this option is only suitable for use in the local area.

- If the skills of working with a welding machine are not enough, the reliability of the design will suffer.

- Making mistakes in the manufacture of the barbecue, non-compliance with the technology will lead to low efficiency, and even inoperability of the brazier.

Do not forget about the main danger - the possibility of an explosion of the cylinder during cutting. To prevent this from happening, you need to properly carry out preliminary work.

Photo: when cutting a balloon, remember safety precautions

Preparation of materials and tools

First - choose a balloon. The recommended volume is 50 liters, so that the brazier is large. Before proceeding with the manufacture of a home-made barbecue, the container is cleaned of fuel residues. Do this carefully, even if it seems that the container is completely empty.

Gas cylinder cleaning

Despite the fact that the main mass of propane in the tank has long been gone, dangerous condensate accumulates on the walls and bottom. To get rid of it, you need:

- release gas naturally - through the valve;

- rinse the bottle.

For complete emptying, the container is turned upside down. To understand if gas is coming out, the valve is moistened with soapy water - it will bubble. Another way is smell. Due to the presence of odorizers in propane, the fuel smells strongly, especially if there is a lot of it in the cylinder. Therefore, the container should be cleaned outdoors, preferably away from people so that no one panics. And, of course, away from sources of fire.

Photo: sawed off the propane valve

Flushing the cylinder is carried out as follows:

- The valve is sawn off. They do it together - the assistant constantly pours water on the place to cut it so that the balloon does not explode due to heat and sparks.

- Pressurized water is fed into the container through the hole. In the process, the balloon is shaken to rinse the walls well.

- The water is left for a few days, after which it is drained. Since it will be filled with mercaptans, the smell will be pungent. We do not recommend pouring such liquid on the beds.

To prevent the water from smelling, potassium permanganate is added, which causes the oxidation of odorizing compounds.

Getting rid of the strong smell of gas is not easy. To finally bring it out, the cleaned and sawn balloon is burned from the inside.

Tools and additional materials

For further work you will need:

- Bulgarian;

- drill;

- welding machine;

- metal hinges and a handle for the lid;

- steel pipes to create legs.

If the work is carried out alone, rivets for temporary fastening of the cover will also come in handy.

Mangal manufacturing technology

While the container is being washed, a drawing is created. It is not difficult to design a brazier from a propane cylinder - in the simplest version, the product consists of three elements: a body, a lid and legs. The diagram of a brazier-steam locomotive with a chimney for smoking looks more complicated. On the drawing, mark the dimensions, determine the location of the lid, cuts for skewers, fasteners for the grill grate, etc.

Drawing: brazier

The main work consists of three stages:

- sawing the balloon

- leg welding,

- cover installation.

An additional stage is decorating the finished barbecue.

Marking and cutting

To divide the container into a brazier and a lid, a semicircular part of the container wall is cut out. The circumference of a standard propane tank with a volume of 50 liters is 96 cm. Marking is easy: there are marks on the tank that you can start from.

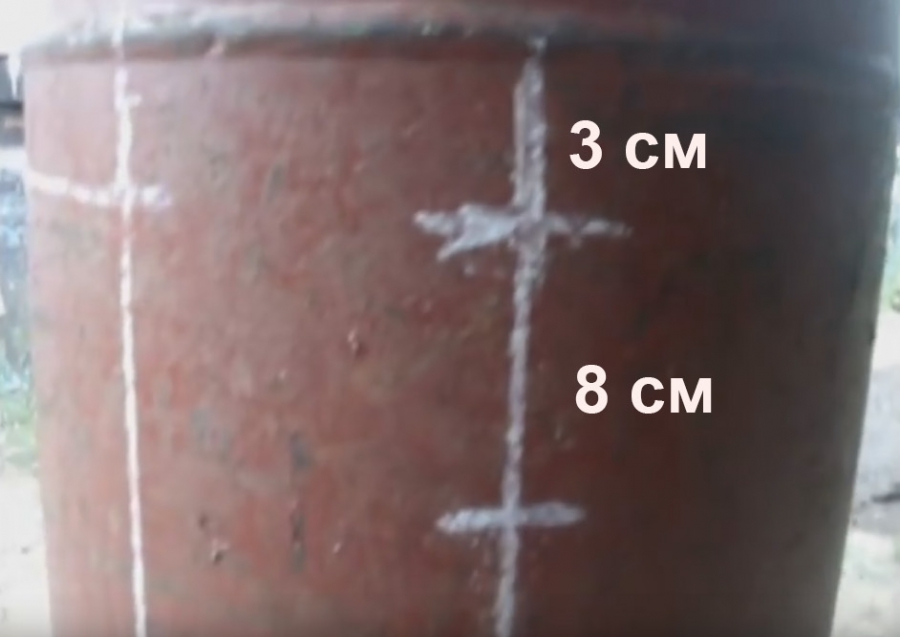

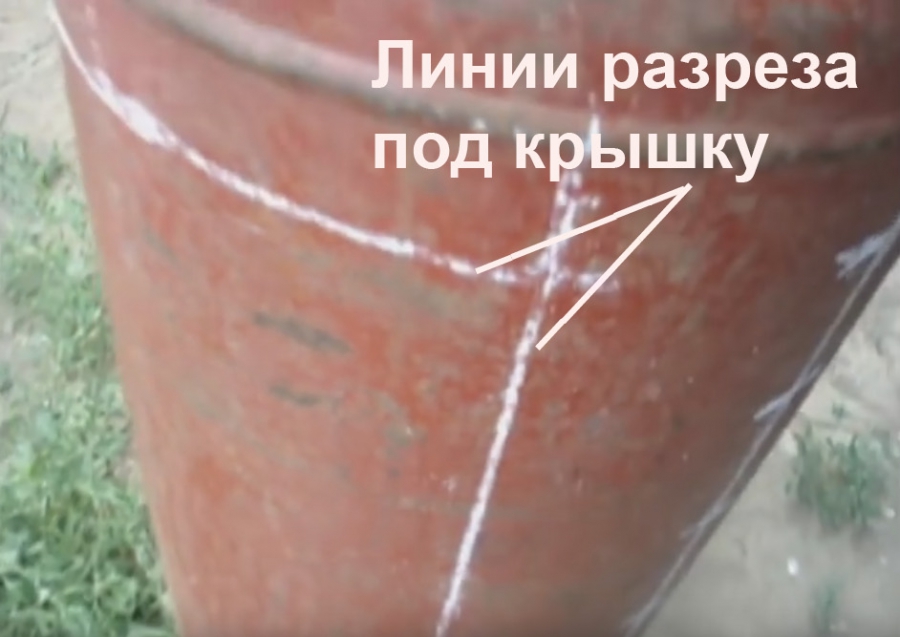

A welded seam runs along the entire length - 24 cm are retreated from it in both directions and the boundaries of the hole are applied. Immediately make notches for fastening skewers. The extreme marks are located 3 cm from the welding rings; intermediate - arrange with any step, for greater convenience, a distance of 8 cm is recommended - then 6 skewers will fit. If you want to leave room for the grill grate, reduce the pitch between the notches.

Next, the balloon is sawn with a grinder. The wall thickness is 3 mm, so it is not difficult to cut the container. They start with longitudinal lines, and then move on to transverse markings - otherwise you can get injured when the wall moves away from the cut with force. It is important to use personal protective equipment - a mask, gloves.

Cross cuts are made by shifting 10-15 mm from the welds. At these points, the metal is doubled, and shifting will save a little time and part of the grinder circle. In addition, a barbecue grill cover will be conveniently placed on the bottom layer.

After cutting the wall with a grinder, cuts are made under the skewers. Just below the drill, holes are drilled for the passage of air. The same gaps are made at the bottom of the barbecue. Only the bottom and the lid of the cylinder are not touched so that the wind does not blow out the coals.

Lid

At the second stage homemade brazier equipped with a lid and a handle. This part is welded with metal loops - fasteners can fail under the influence of high temperature. To make it convenient to work alone, the cover is temporarily fixed with rivets. Loops are placed at an equal distance from each other.

Metal is used for the handle, since wood and plastic can deform, burn or melt during operation.

legs

Depending on whether the brazier is stationary or portable, the shape of the legs for it is selected. For the mobile version, these parts are made of pipes or metal corners, with wide platforms welded to the ends so that the brazier does not go underground under the influence of its weight. The height of the products is selected individually; It has been experimentally established that it is more convenient to put the brazier on legs 20-30 cm long.

Photo: finished legs from a metal pipe

A stationary barbecue, as a rule, is mounted on a concrete or brick foundation. In addition, the design can be stylized - for example, forged wheels can be welded to give the brazier the look of a steam locomotive.

This balloon barbecue is ready. All that's left is the finishing touches - welding on the grill mounts, coating the body with heat-resistant paint, and other finishes. To add, a chimney is welded to one side wall, and a firebox to the other. When the lid is closed, a smoking chamber is obtained.

Thus, it is not so difficult to turn a standard gas cylinder into a universal fryer, the main thing is to observe safety precautions when working. A propane tank will allow you to realize various design ideas brazier, which will be a great addition to a country holiday on the weekend.

footage

Summer is the season for picnics, which cannot be imagined without kebabs and grilled vegetables. There are many ways to prepare dishes in nature, which require a barbecue. You can buy a finished design in the store or place an order in the workshop. But it is better to make a brazier from a gas cylinder with your own hands. So you can get an exclusive product that meets the stated requirements and personal preferences.

Barbecues are made from propane or oxygen cylinders of high quality metal. They are characterized by solid standard sizes, regular geometric shape, good capacity, the ability to place a large number of skewers. The height of the structure can be adjusted to the height of the owner, which cannot be obtained from factory models. This will enable a person not to bend while cooking meat, but to stand straight.

Experienced craftsmen can, using their own imagination, using welding, fittings and metal, create unusual products that will become an original exterior decoration. country house or summer cottages, which is clearly proved by the photo of barbecue grills from a balloon.

The design of such a product is easy to manufacture. It is enough to carefully study the drawing of the brazier with your own hands from a balloon and, with minimal skills, create a design. This option is the most budgetary. After all, the product is made from an old unusable cylinder, so the basis of the design will be free. Estimate how much a brazier made with my own hands, can be based on the cost of additional components of the structure.

Since the gas cylinder has thick walls, the finished structure will be able to withstand high pressure and high temperature without the risk of deformation of the product. Therefore, the service life of the brazier increases. In addition, the bottom does not burn through during prolonged contact with an open fire, which means that after cooking there is no need to fill the product with water. If you make a barbecue with a hinged lid, you can leave it on the street without fear negative impact atmospheric precipitation. In addition, a brazier with a lid can be used as a home.

The structure can be completed additional elements which will increase its functionality. The brazier from a cylinder is easily transported and installed on another place.

Among the shortcomings, the following can be distinguished:

- due to the large dimensions, the design may not fit into the interior of a small courtyard;

- the brazier has a significant weight, so two people will be needed to move it;

- the design has limited space for logs, so it is better to use coal as a raw material.

This will make it possible not to wait too long until the firewood burns out and enough space is freed up for placing skewers.

Brazier from a gas cylinder: design options

From an old gas cylinder, you can make several options for barbecues:

- traditional design without cover and with it;

- B-B-Q;

- smoker;

- smokehouse.

The last three varieties differ from classic look brazier. Barbecue is represented by a simple design, consisting of a part of a cylinder, inside of which there is a grid for placing products and an area for coals. The cut off part of the balloon will act as a lid and be hinged.

There is a firebox in the smokehouse. In order for the structure to cope with the task, it must be airtight. To do this, half of the bottom of the product is removed. A firebox is made of metal sheets and welded to the main structure. A chimney pipe is attached to it by welding, which helps to remove smoke from the smokehouse. After the construction is completed, it should be heated several times with firewood and only then proceed to smoking.

Useful advice! For the manufacture of the firebox, you can use another cylinder.

The most complex and multifunctional construction is the smoker, which is also called a steam locomotive. For the manufacture of the structure, you will need several cylinders, each of which will perform its function. This device combines the capabilities of a barbecue, barbecue, smokehouse and grill.

Necessary tools and materials for making a brazier from a balloon with your own hands

The basis of the design is a gas cylinder measuring 96 cm long, 30 cm wide, with a volume of 50 liters. You can also create a brazier from a similar product for 80 liters, which has an increased diameter, which helps to increase comfort during ignition. Such a product is characterized by good capacity, allowing you to use the entire length of standard skewers. This greatly facilitates the process of cooking barbecue for a large company.

There should be no external damage on the structure that contributes to the formation of small foci of corrosion, which, under the influence of open fire and high temperatures, will turn into holes. After some time, such a fate will befall the entire structure. Even if the brazier is covered with heat-resistant paint, all defects will be found. Holes can be welded, but this will spoil the appearance of the product.

Useful advice! To create a small mobile barbecue, you can use a traditional 27 liter cylinder.

Before you make a brazier with your own hands, you should prepare the following materials and tools:

- electric drill with drills for metal;

- welding machine;

- clamps for fixing metal components;

- pipe wrench;

- grinder;

- hammer;

- chisel;

- screwdrivers;

- electrodes with a diameter of 4 mm;

- cleaning and cutting;

- scriber;

- nozzle-brush for a drill;

- sprayer or brush for further coloring the product;

- metal pipe with a diameter of 100 mm for the chimney;

- elbow with a radius of 900;

- door hinges;

- metal corner;

- metal handles that will be attached to the lid;

- grill for creating a barbecue;

- fasteners in the form of nuts, rivets, bolts;

- priming;

- paint;

- solvents;

- various decorative elements.

Preparatory stage before disassembling the cylinder

Before you properly make a brazier, you should prepare a balloon. It is necessary to remove the remaining gas from it by unscrewing the valve with an adjustable water wrench and a steel pipe used as a lever. Removing the fitting on the cylinder is quite problematic, since it is securely soldered to the body. To prevent the container from turning, a stop corner should be attached to its bottom.

At the junction of the valve with the body, you can apply a "vedeshka" and wait a few hours until the thread sags. Perform the procedure only in the open air, away from potential sources of fire and other places where ignition may occur.

Useful advice! To make sure that the cylinder is empty, the valve should be soaked in soapy water. If it bubbles, then the gas is still coming out.

After the cylinder is completely empty, it is recommended to turn it upside down so that all the accumulated condensate is poured out. Next, the container is filled with water, which helps to displace all vapors and residues. To do this, the water hose is connected to the installation site of the tap. Water should be supplied under low pressure. This simple operation helps to prevent dangerous situations associated with the disassembly of the product. The tap is put in place, and in this state the structure remains for 2-3 days to remove all odors.

The optimal size of the brazier: marking

While the water is in the cylinder, marking is carried out according to a previously developed drawing of a brazier from a gas cylinder with the indicated dimensions. Usually, a product with a volume of 50 liters with an outer diameter of 96 cm is used for the barbecue. The dimensions of the barbecue from a gas cylinder are: length - 98 cm, width - 30 cm, height excluding legs - 30 cm. This design is enough to cook six servings of shish kebab.

Marking is convenient to carry out from the longitudinal seam. The diameter of the gas cylinder is divided into four equal parts - 24 cm each. This value is laid off from the seam on both sides. To the right and left of the circular seams, 3 cm recede, and marks are made every 8 cm. Thus, 6 marks are obtained for the future placement of skewers. Holes with a diameter of 1 cm are drilled in them.

Useful advice! Despite the fact that the brazier from a cylinder is a simple product, it should be initial stage make a small drawing of a brazier from a gas cylinder with dimensions and an indication of the points of attachment of individual elements.

From the line on which the markup was carried out, 10 cm is laid up, i.e. from the middle of the seam, 34 cm is obtained. In this place, the brazier cover will end, which is marked in the next step. It occupies the distance between the first drawn line and the one just marked. A straight line is drawn between them, stepping back 3 cm from the circular welds. Also, they are moved 10 cm down from the initial marked strip for future fastening of the legs, which should be placed parallel to each other.

Useful advice! If metal rings are located inside the product, the cut should be made in such a way that they are not damaged. They may become the support of the lid in the future.

How to make a brazier with your own hands from a balloon: a sequence of actions

Based on the markup, the product is cut. You can study the process in detail on the video "Barbecue from a gas cylinder with your own hands." To do this, it is recommended to use a grinder or gas cutter. The cut should start from the middle and move towards one of the edges. The grinder disc must be kept perpendicular to the balloon. Since the product has a large wall thickness and the sawing process occurs with great intensity, in order to avoid premature burning of the disc, it is recommended to cut in some places not completely. Such areas can subsequently be eaten with a chisel.

Related article:

Features and types of structures, interesting options design and photo, popular projects with drawings and step by step description manufacturing technology.

When cutting the balloon, it is necessary not to reach the circular seams by 3 cm. Having made a cut along one line, the loops should be welded. If you cut off the cover completely, the action will be more difficult, since the cover will have to be fixed at the same distance, which will be inconvenient for one person.

To attach the hinges, the seats must be cleaned and sanded. The elements are fixed with rivets and welded. Next, proceed to the installation of fasteners. After that, the cutting of the cylinder along the lines is completed. In this case, the lid will rotate, but not fall. The water from the cylinder can be drained at this stage. It is recommended to do this away from residential areas, since methane has a pungent odor that lasts for several days.

When making a removable cover, care should be taken that it does not fall inward. To do this, metal strips are welded to the transverse edges of the product.

So that the lid in the open position does not break out the hinges, leaning back, it is necessary to weld a piece of the corner between the hinges along the cut line. Its width can be 3-4 cm. Such stops are made on both sides of the lid - left and right. By unbending the corners, the distance required to open the lid is adjusted. It is chosen in such a way that when closing this element, it is not necessary to lean forward to get the handle.

How to make a brazier from a gas cylinder: handles and holes for oxygen access

The next step is to weld the handle. It can be of any kind and be made of various improvised materials that are resistant to heat. The most primitive option is to weld a piece of concave reinforcement in an appropriate way. In this case, it is advisable to attach a piece of wood to it so that you can grab the handle. Such a part can be attached to the product using bolts.

To prevent the lid from falling inward, it is necessary to weld a metal strip 2-3 mm thick and 3-3.5 cm wide from the inside to the cutout around the entire perimeter of the product. Holes with a diameter of at least 1 cm are drilled along the previously applied marks for holes for skewers. On the other hand products (opposite each of the holes) cuts are made to the welded plate, which are necessary for installing skewers.

The next step is to make slots for air to enter the bottom of the product. This must be done because the construction of the structure is closed. And this means that coals and firewood will burn badly in it without oxygen. To do this, the brazier should be turned upside down. From the seam is deposited 10 cm in both directions. A distance of 10-12 cm is measured from the resulting lines. Thus, longitudinal stripes of a given width are obtained. Slots are made across the strip every 5-7 cm for air to enter. The strips can be replaced with holes, but they will require a large number, which will take a lot of time.

It is not recommended to make holes in the bottom of the cylinder. Firstly, the factory seam should not be touched - this can lead to a decrease in structural rigidity. Secondly, at the bottom, any holes are clogged with fat mixed with ash and ash. In the future, such a mixture can clog holes and impair air flow.

The final step is to cut the tap and weld the resulting hole. Also in this place it is possible to provide a metal pipe to remove smoke and ventilate the brazier in the closed state. The brazier is ready, it remains to attach legs to it. You can see all the stages in detail on the selection of photos “How to cook a barbecue”.

Making legs for barbecue from a gas cylinder with your own hands

Do-it-yourself legs for a barbecue from a gas cylinder - the photos clearly confirm this - can be made from any material: fittings, a profile or round pipe, a strip of thick metal. Corners or pipes are sawn into four parts about 50-70 cm long. The elements are welded to the body in previously marked places at the same distance from each other so that they form a rectangle of the correct shape.

At the ends of the support legs, it is necessary to weld square metal plates, thanks to which the brazier will be more stable on the surface. You can also use two metal profiles connected in parallel to two other legs at the bottom of the product.

When making legs from sheet metal, two strips 40 cm long and 20 cm wide should be cut. The tapes are bent in the form of an arc along the diameter of the product. Legs are welded to their ends. Further, to create the necessary rigidity and strength, a transverse bar is attached to each pair of legs below. Between two racks a corner is welded with a length corresponding to the value of the product.

popular and simple option for the legs can serve as a design from sewing machine. The brazier can be mounted on wheels, which will make it easy to move it around the yard.

If you use a profile pipe for the legs, they will look like an inverted "T", and they can also be welded to the middle of the product. You can make a support in the form of a frame with a shelf at the bottom for placing firewood, coal, bowls, etc.

A good option is to make legs from rebar and a round pipe. In this case, you can get a portable design. Pieces of pipes of the required diameter are welded to the brazier body, into which reinforcement bars of the required length are inserted. You can, on the contrary, weld pieces of reinforcement and put pieces of pipes of a suitable diameter on them. However, it should be noted that when moving the barbecue, the legs may fall out. Therefore, it is recommended to cut threads for them. Manufacturing various options supports can be studied on the video "Barbecue from a gas cylinder: manufacturing of support structures."

Painting a brazier from a propane cylinder

To paint a barbecue, smokehouse, brazier from a gas cylinder with your own hands, you should use heat-resistant paint, since the possible temperature in the brazier can reach 800 0C. Painting should protect the metal from the effects of corrosion and temperature changes when it comes into contact with a hot body cold water. When heated, the coating should not emit elements harmful to human health and enter into a chemical reaction with other substances.

Before painting, the surface of the gas cylinder is cleaned of old paint. The procedure can be carried out using sandpaper or a special metal nozzle for a drill. Further, the entire surface is degreased with a solvent, acetone or alcohol and coated with a primer. Heat-resistant enamel before application should be mixed well until a homogeneous state is obtained. It is necessary to remove all clots and sediment from it. In case of too thick consistency, the paint is diluted with a small amount of thinner.

The paint is applied by sprayer or brush in several layers until a smooth and beautiful surface is obtained. Each layer must dry completely before applying the next. Temperature environment must be above 20°C.

The most popular heat-resistant paints are acrylic mixtures in cans. With a unique composition, they are safe, effective, quick-drying and durable. Also, the paint is characterized by anti-corrosion properties. It is sprayed at a distance of 20 cm and applied in several layers, each of which dries for 2 hours. The palette of shades is quite wide, but the most popular are silver and black.

Brazier from a gas cylinder: photo of product varieties

Using the instructions for making a brazier from a gas cylinder with your own hands, which you can buy ready-made from experienced craftsmen, it is easy to make a barbecue. To do this, a corner is welded along the long side of the body of the product. The result is a shelf on which a lattice welded from reinforcement bars will be located. A convenient option would be to separate the zones in the barbecue grill with a net and places for skewers. You can also create a stationary brazier. To do this, small tables from the corners are welded on the sides and front of the structure.

An alternative to coloring is the stylization of the brazier under the "antique"

Another design option from a balloon is to create a brazier-smokehouse with your own hands. In this device there is an additional element in the form of a firebox. To create it, strips are cut from the bottom of the cylinder, then half of the bottom is cut out. Thus, a place is obtained for organizing a firebox, which is made of dense metal sheets 2-3 mm thick and welded to the bottom. The result is a one-piece hermetic structure, which is clearly shown in the photo of the smokehouse.

It is also necessary to organize chimney. It can be purchased at a hardware store or made from a gas cylinder of a smaller diameter. It is recommended to improve the design and install a motor that will rotate the skewer with meat, which can be seen in the video “Barbecue-smokehouse with your own hands from a gas cylinder”. Drawings, photos, of which there are a large number of Internet, will also help to complete the design and get a multifunctional building.

Another unique structure is the brazier-steam locomotive. The design is made of several cylinders different diameter, barrels and main pipes. Such a product combines a barbecue, smokehouse, barbecue and do-it-yourself. The structure is complemented by forged elements that give the structure an original and aesthetic appearance.

Using imagination and a creative creative approach, you can make a brazier in the form of a pig, a dog, a house and even a submarine, which is clearly demonstrated by photos of braziers from a gas cylinder with your own hands.

How to make a brazier from car disks

Brazier from car discs combines a barbecue, a smokehouse, a hob and a grill from a gas cylinder. The metal structure can be made from old rims from the car. You should take those that are made of solid steel, not aluminum alloy.

The brazier from automobile disks is carried out different ways. For the simplest design, one element is enough. The inner part is cut out of it, forming a container similar to a bowler hat. If there are too large holes in the bottom, a metal plate must be provided. However, the holes should not be completely closed, as the coals must be blown through to maintain heat. From the sides of the bottom you need to weld the legs from the pipe.

On such a grill, you can fry not only shish kebab strung on a skewer, but also barbecue. To do this, the structure should be covered with a metal grate. It would be more appropriate to make it removable. For the convenience of moving the brazier, handles are welded symmetrically on the sides of the structure. To maintain the heat on the side of the disk, you can make a window.

To cook the brazier more complex design, you will need two disks of the same size. On one of them, a partition is cut out with a gas cutter. The elements are placed on top of each other and welded around the perimeter. The partition of the second disk is the bottom for the first. It will be convenient to have a kettle here. In the lateral part of the lower disk there is a window for throwing firewood.

Another option that deserves attention is the welding of two elements to each other, in which the middle is pre-cut. In the side part of the structure, a window is made through which firewood is fed into the firebox. The upper part of the structure is equipped with a grill that turns the brazier into a barbecue.

How to make a brazier from a barrel and a pipe

To create a brazier from a barrel, you will need a container with a volume of 50-60 liters with a diameter of 40-50 cm. The product must have a wall 2-3 mm thick. From the barrel, you can create two braziers. To do this, the product should be cut in half.

The manufacturing process of the structure is similar to the creation of a brazier-smokehouse from a gas cylinder. Only the dimensions of the product will differ, on the basis of which marking is performed for future cutting. However, at the preparatory stage, it is not necessary to fill the container with water. In the side part, a round hole for the chimney should be cut from above, and at the bottom - for ventilation.

A good solution is also to use another barrel mounted on the side cover as a pedestal, where a full-fledged smokehouse is organized. To create a design, you can use the drawings found on the Internet.

Useful advice! A 27 l gas cylinder can be attached next to the barrel, which can be used as a place to store coals.

The design is quite often made of a metal pipe. This is a more time-consuming option that needs the use of additional material. A metal sheet is used to create the walls of the structure. If a smoke exhaust pipe is provided, its diameter should be 70-100 mm.

Important! Do not use a fuel barrel for barbecue. The specific smell cannot be eliminated by anything.

Today you can buy a ready-made brazier from a gas cylinder, the average price of which is 5,000 rubles. but homemade design It will cost even less and can last for many years with proper operation and proper care. Having equipped with additional elements a brazier from a gas cylinder, which you can buy in specialized stores, you will get a multifunctional facility for smoking, grilling and barbecue. A creative approach to the design of the product will allow you to create an original design that can decorate the site.

Making a brazier, grill, barbecue, smokehouse with your own hands from a gas cylinder: video instruction

The owners of suburban areas and cottages are trying to make outdoor recreation comfortable and complete. And what rest without fragrant kebabs with a pleasant smoky aroma? In this article we will talk about making a grill from a gas cylinder with your own hands. Photo and detailed instructions will help you understand the intricacies of this process. So let's get started!

How to make a barbecue grill from a gas cylinder?

Gas bottle - suitable material for making barbecue grills. Firstly, the walls of the container are quite thick, and at high temperatures they will keep their shape without deformation, and secondly, the shape of the container will make the grill original and roomy enough. The main thing is to choose suitable option by capacity.

The gas cylinder will need to be sawn with a grinder to make a hole in the cavity. The sawn part will play the role of a lid, so you will need strong hinges. All installation and cutting work must be carried out in compliance with safety regulations. In addition, you need to have knowledge and experience in working with a welding machine, grinder, drill and other equipment that will have to be used.

A design made from a gas cylinder can have different functions and purposes. Here are a few options that you can do with your own hands:

- Portable design. In this case, a small balloon is used. If necessary, it can be put in the trunk and transported to the place of operation. This brazier is convenient to take with you to nature.

- Portable device. This type of barbecue is larger in size, but if desired, it can be moved a short distance. There are models of large barbecues that are equipped with wheels. If necessary, you can move the brazier to the right place. The whole structure is disassembled into its component parts, but it is inconvenient to take it with you on a long trip.

- Stationary design. Such a brazier, as a rule, is universal, has several additions in the form of a smokehouse. The design is built into concrete foundation, and it is not possible to move or transport it. To exit the smoke, the brazier is equipped with a pipe; there may be special compartments in which it is convenient to store firewood for ignition.

Necessary materials

Before starting work, check that you have all the equipment in stock. To make a grill from a gas cylinder with your own hands, you will need:

- empty gas cylinder;

- ruler, level;

- drill with drills for metal;

- grinder with a set of discs for metal carving;

- hacksaw for metal;

- welding machine;

- electrodes of the desired diameter (2-3 mm);

- corner 40 × 40 mm (length - 6-7 m);

- door hinges - 2 pcs.;

- wooden handle with metal base;

- paint with high level protection against high temperatures;

- brushes, rollers;

- protective glasses;

- fabric gloves;

- rivets, bolts;

- steel pipe with a diameter of 10 cm with a 90 ° elbow (for a chimney);

- adjustable, wrenches and gas wrenches.

Choice of gas bottle

Gas cylinders are made of thick steel 3 mm thick. Therefore, they are very convenient to use for the manufacture of barbecue. Perhaps you already have old cylinder, which is lying in the country. If not, then it can be easily purchased at a bargain price at flea markets or classifieds sites.

Inspect the bottle carefully. There should be no signs of severe corrosion and rotten areas on the surface. Shake the bottle and determine if there is any residual liquid propane gas inside.

Decide on the type of your future design. If you want the brazier to be portable, then you should choose a small volume cylinder. This one can be taken with you on trips, but it is not very convenient to use it, since there is not enough space inside for cooking food.

The most popular and widespread type gas cylinders are containers of 50 liters. They are most often taken for the manufacture of the grill. If you want to attach a smokehouse, then use one cylinder for 50 liters and one for 30 liters. The containers are connected with a sealed seam. The smaller cylinder is mounted slightly lower. Such a simple method will allow you to make a smoker-grill from a gas cylinder with your own hands. The fuel will be placed in a smaller container, the smoke from which will flow into the main chamber, and from there through the chimney to the street.

And how to make a grill from a car gas cylinder? If you want to get a large grill, then it is better to use an 80 l cylinder. The manufacturing scheme for all types of cylinders is the same. The only difference is the scale of the work. To fix the lid of a large 80 l cylinder, you need to use 3 loops, not 2. This is due to the greater massiveness of the moving element.

You can make a grill from a freon cylinder, this container is small, so you get a compact portable version. But most often these cylinders are used to organize a smokehouse.

Drawing, cylinder preparation, installation

Create a detailed plan that will indicate all the necessary dimensions that will help you not to make mistakes when performing metal cutting work.

The lid of the future grill should be located so that the lower part of the cylinder is deep enough, because coal will be placed there.

The balloon itself must be prepared for work. Let off all the gas first. Even if the cylinder is empty, there is still residual gas. Open the valve and wait a while. Turn the bottle upside down and drain the condensate. To control the release of gas, you need to apply soap suds to the valve, it will help determine whether all the gas has come out or not. When the foam stops bubbling, you can proceed to the next step.

Now cut off the cylinder valve. Better enjoy hand tool, so you can control the resulting sparks and avoid overheating the tool. At this stage, you need to constantly water the saw cut with cold water. Insert the hose into the hole and fill the bottle with water. Leave it with water for a day. During this time, the water will dissolve any remaining hydrocarbons. After that, the water can be drained away from the buildings. You can proceed to the next step in the manufacture of the grill from the cylinder.

Step-by-step instructions for making a grill

Now let's move on to the next question. Consider how to make a barbecue grill out of a gas cylinder. We take a standard 50-liter propane gas tank as a basis. The outer diameter of the balloon is 96 cm, dividing this value by 4, we get 24 cm. The balloon has a rounded shape, so to install it you will need a special metal structure that will play the role of a stand. It is best to use metal with a thickness of at least 4 mm for these purposes. You can use chalk for marking. We draw marking lines along the side seams, so it is easier to maintain symmetry.

We draw a line that will connect the upper and lower seams. Then we measure 24 cm along the seam and make two more marking lines. We connect them horizontally. It turns out a curved rectangle. This will be the lid of the grill. All edges must be cleaned with a metal shank. Try to make the edges as even as possible, this will help achieve better sealing of the closed container.

Corners are welded inside the cylinder, which will not only play the role of supports for the gratings, but also act as frame elements to maintain the shape of the cylinder. At very high temperatures, the metal will not deform.

Be sure to drill a few holes in the bottom of the container. Oxygen from the air should get into the brazier, which will allow you to quickly make a fire and keep the coals burning. If you use not a grill, but skewers, then you need to cut recesses for them from the side of the lid and make holes on the other side. It is in these holes that the skewers will be inserted.

In the place where the valve was located, we make a wider hole. This is where the chimney pipe will be located. The cut diameter should be approximately 8 cm.

Welding

Get ready to do the welding. Wear a special welding mask that will protect your face and eyes from exposure to bright light and flying hot electrode elements.

First, weld the handle to the lid of the future barbecue, this will allow you to fix it at the moment of welding with a loop. So it will be more convenient to hold the movable element. Now we weld the loops to the main part of the cylinder and the lid. Consider all the details: so that the lid does not lean back too much, you need to make a limiter. It could be a metal corner. Weld a small piece in the gap between the loops.

Now you need to fix. Make sure that the welding seam is even and neat. The brazier should be not only functional, but also beautiful.

For ease of use of the design, you can make an additional metal stand on one side. To prevent water from flowing into the chimney during rain, build a fungus on the pipe and weld it to the end of the pipe using metal plates 10 cm long.

We make a stand for the structure

The stand can be made from profile pipe with a diameter of 20-30 mm or take reinforcement. If you plan to make a stationary barbecue grill, then it is better to immediately weld the legs to the cylinder. You can make a full-fledged stand from which you can remove the cylinder and move it to another place.

Metal elements must be bent along the outer diameter of the cylinder and welded to the arcs of the legs. Remember, in order for the structure to be stable, you need to make a sufficiently large span between the legs. So the brazier will not roll over and will not tip over. The height of the legs is selected individually. It is most convenient to place the brazier at the level of the belt, so you do not have to bend down to carry out various manipulations with the hearth.

If the legs are made in the form of a stand, then it is necessary to weld horizontal corners to the cylinder itself, which will fix the container in a certain position and prevent it from scrolling.

How to paint the balloon?

It is impossible to prime the surface before painting, since the primer will crack and peel off at high heat along with the paint applied to it. Before painting, the entire surface of the cylinder must be sanded. Particular care should be taken to cut the saw cuts and holes made with a drill. Degrease the surface after cleaning.

Paint should be chosen only heat-resistant. Carefully read the instructions on the spray can or can of paint. There is indicated temperature regime paint operation. Black and silver paints, as a rule, withstand temperatures of +600 °C (4 hours) and +400 °C (long time). For other shades of paint, the temperature of short-term heating is +400 °C, long-term - +200 °C.

It is most convenient to use heat-resistant paint in spray cans. It is applied in an even layer, and even a child can make the coloring process itself. Remember about safety: be sure to take care of respiratory protection. Use a protective mask, you can buy it at a hardware store. Put rubber gloves on your hands.

One coat of paint dries approximately 8-11 minutes. After complete drying of the first layer, apply the second. Make sure all hard to reach places are painted. This is important, since the main function of the paint is not aesthetic, but protective. The paint surface prevents the formation of corrosion on the metal.

Some additions

Stationary grills from a propane tank can be decorated with forged elements. These can be openwork legs, special stands in the form of a small table, firewood compartments and more. You can mount a thermometer into the wall of the cylinder, this will allow you to better organize the cooking process, controlling the temperature inside the container.

You need to paint the grill container only from the outside. The paint on the inside will be useless, as it will peel off in any case from intense heat, open flames and mechanical stress.

If you make a damper in the chimney, then you can control the exit of smoke. This will be useful if you plan to use the container as a smokehouse.

To create a multifunctional device, you can use several cylinders. In the photo - a grill from gas cylinders different size. Small - for organizing a brazier, horizontal large - as a grill, vertical large - as a smoking chamber. All containers must be connected in series with sealed seams. If you want to make a cold smoking chamber, then it must be connected to a 3-meter brazier metal pipe.

Finally

How to make a grill from a gas cylinder with your own hands? It's not difficult at all. The main thing is to choose the right material and do all the work carefully. All types of work are quite within the power of the average person who has initial experience and knowledge in the field of application welding machine and Bulgarians. Remember that all actions performed are dangerous, so take the necessary measures to protect yourself. You can make a grill from a gas cylinder with your own hands in 1-2 days, if you act without helpers. Perform all types of work strictly according to the instructions.

An old gas cylinder is one of the most useful things in the household. What they don’t do from it: stoves, potbelly stoves, barbecues and barbecues. and all because the form is almost ready. There are minor alterations that take only a few hours. For example, a brazier from a gas cylinder with your own hands can be made in three or four hours (this is if the legs are not done).

Safe Disassembly

Before you start working with the cylinder, it is necessary to remove the remaining gas from it. The operation is simple, but reliably prevents possible troubles: the container is filled with water. It displaces all vapors and residues.

First, the tap is unscrewed, the water hose is connected and water is supplied under a slight pressure. When the entire volume is completely filled, you can begin to cut the metal.

Cylinder marking

Most often for a brazier they take propane tank for 50 liters. It turns out optimal size for cooking 6 servings of barbecue. These products are standard, because the markup will be common to all.

The outer diameter of the balloon is 96 cm. It is perfectly divisible by 4: it turns out 24 cm. There is also a mark, relative to which it is convenient to make markings: this is a longitudinal seam. With respect to it, it is worth postponing all distances: then everything will be smooth, without distortions.

First, we set aside 24 cm from the seam in both directions, draw lines. Putting the balloon horizontally, seam down, on one of the lines we make markings for skewers. We retreat 3 cm from the circular seams on the right and left, and then we put marks every 8 cm. We get 6 marks. They will need to drill holes with a diameter of about 1 cm.

From the line on which the markup was carried out, we set aside 10 cm upwards (34 cm will be obtained from the seam-middle). This is where the lid of our barbecue will end.

Next, mark the lid itself. This will be the distance between the first marked line and the one just drawn. Between them, stepping back from the circular welds of 3 cm, we draw lines. You and I drew a brazier cover on the balloon. It occupies less than half the diameter (in the photo it turned out below).

We make a brazier from a gas cylinder

All these manipulations are carried out with a cylinder filled with water. Marked, and first of all we cut along the line to which the cover will be attached (see the photo below). Just do not forget: when cutting the balloon, do not reach the circular seams by 3 cm.

After making a cut along the entire length of this line, stop. Further cutting is not necessary yet: we will immediately weld the loops.

If you first cut off the entire lid, it will be difficult to weld the hinges: you will have to somehow fix the lid, hold it at the same distance. It is impossible to do this alone, you will need an assistant. Stopping after the first cut along the line, it is easy to do everything alone.

Having welded the hinges, we continue to work as a grinder - they cut off the door, and it turns and does not fall. Now you can pour out the water from the tank.

Further, so that the open lid does not fall back and break out the loops, we weld pieces of a corner along the cut line between the loops (see the photo below). A width of 3-4 cm is enough, and cut off the corner as it is - 40 * 40 mm or 50 * 50 mm. Such stops are needed on both sides of the cover - on the right and on the left.

The distance to which the lid will open is changed by unbending the corners. Choose such a distance that it would be convenient for you to close it - you did not have to lean forward, reaching for the handle. But at the same time, it must not be pushed too far forward, so that it does not slam shut and hit your hand.

We weld a piece of the corner between the loops - this will be a stopper for the lid

The remaining bottom rim is easy to remove if you make an incision. It is advisable not to touch the side (circular) seams. O-rings are laid in them, which rigidly hold the entire structure of the brazier. That is why, when marking the lid, we retreated a few centimeters from them: so that the brazier is strong and reliable.

We attach a handle to the lid. She can be anyone. If there is something suitable in the "gash" we use it, no - you can just weld a piece of fittings curved accordingly. It is only desirable to adapt another piece of wood so that it can be taken by hand.

The next step in making a brazier from a gas cylinder is necessary so that the lid does not fall inward. To do this, we cut out a strip about 3 cm wide from metal with a thickness of 1-3 mm. And weld it to the cutout in the cylinder.

On the other side, on the welded plate opposite each of the holes, we make cuts. This is also a place for skewers.

The next step is to cut holes in the bottom for air to enter. The design of the brazier is closed, and without this, firewood and coals will burn badly. Therefore, we turn the brazier upside down, and set aside 10 cm from the seam in both directions. Further, from each of these lines, set aside another 10-12 cm and also draw lines. It turned out that at an equal distance from the central seam, we have two strips 10 cm wide. In these strips, we cut holes for air supply with a grinder every 5 cm. If you wish, you can not make strips, but drill holes, but there should be a lot of them, and making strips will take less time.

About why holes are not made at the very bottom. Firstly, it is undesirable to touch the seam. It gives rigidity to the structure. Secondly, any holes at the bottom are quickly clogged with grease mixed with ash and ash. Then this mixture emits a lot of smoke, and through the clogged holes the air enters very badly, you have to constantly fan the firewood and coals and often clean the holes.

The final touch is to cut off the tap and weld the hole.

The barbecue itself from the gas cylinder is already ready. It remains to attach the legs. How - read a couple of paragraphs below.

What should be the result: a brazier from a gas cylinder with a lid

Simple design

The option described above is convenient, but rather complicated to manufacture. Everything can be made easier. The easiest way is to cut the propane tank in half lengthwise, cut indentations along the edges along the skewer, drill holes in the sides for air to enter and attach the legs. That's all the work.

If there is a desire to make a brazier with a lid, the second half is welded onto the hinges. And so that the lid does not fall through, a strip of metal 3 cm wide is welded to it along the outer and side sides (in the previous version, the strip was welded to the body, and not to the lid).

To keep the open lid from falling, sometimes a piece of chain is used as a stopper. A segment of the desired length is welded to the right and left. But the option with stops at the back is much more practical: the chain gets confused and dirty: when the lid is closed, it ends up inside the brazier.

Barbecue from a barrel

It is desirable to find a barrel of almost the same volume - 50-60 liters - this is the optimal size. Moreover, its diameter should not be too large: skewers usually go 50-60 cm. In order for them to lie tightly on the brazier, at least 10-12 cm of free length should remain. So it turns out that the diameter of the barrel should not be more than 40-50 cm.

Brazier from a barrel with a lid. Production to the smallest detail coincides with the process when using a gas cylinder

If it is wider, there are two ways out - to make skewers according to the required sizes or to weld a corner on the far side from the inside, on which to rest their tips. You won’t be able to win much, but 5-6 cm, depending on the size of the corner, can be won back.

Barrels must have walls at least 2-3 mm thick. By itself, you can not use containers from under fuels and lubricants. You can’t fall them out to such an extent that you can cook food.

The sequence of manufacturing a brazier from a barrel is no different from those described above. It just goes away by itself preparatory stage- There is no need to fill with water. With very different sizes, you will need to make adjustments to the markup - in the direction of decreasing or increasing - see for yourself.

From the barrel, you can also make the simplest brazier - weld the legs to the cut along the container and cut along the edges of the recess for the skewer

They make very functional barbecues out of barrels - they add a container for coal or firewood (also with a lid) next to it. One of these is in the photo.

Although, no one bothers to make the same from a cylinder: next to a 50-liter propane tank, attach the same design, but already 27 liters.

Brazier from a pipe and with a pipe

Building a brazier from a pipe is a little more difficult. In the sense that it will be necessary to weld the ends. All other operations are no different. Even the designs are exactly the same.

Braziers from a pipe - manufacturing will take a little more time: you need to weld the sides

But when using a pipe, there are advantages: since we will weld the sides anyway, why not make a door (in the photo on the left). You can use the old one from the stove - you can put firewood through it, as well as regulate the air supply while the coals are “preparing”.

Barbecue with a pipe

To ensure better traction and so that the smoke does not interfere with those nearby, you can attach a chimney pipe to the side of the barbecue from a cylinder, pipe or barrel. It will add work, but not very much. But it will be more comfortable to use: the smoke is good on barbecue, but they don’t feel like breathing at all.

Braziers with a pipe are more comfortable - the smoke goes up. Everything can also be arranged in different ways.

Making legs

They can be from a corner, a round or shaped pipe, fittings, a strip of thick metal. What is in the economy, then use it. Some ideas are in the photo below.

The simplest legs from a pipe and a corner were welded to the bottom. You can make spacers at the bottom, and arrange a shelf on them

Almost the same can be done from strips of steel of great thickness.

Convenient legs for a brazier from a propane cylinder can be made from a profile pipe. They can be in the form of an inverted "T" and welded to the middle. You can make a support in the form of a frame by making a shelf (or several shelves) at the bottom for firewood, bowls, etc.

You can make legs from a round pipe and / or fittings. If you want to have a portable brazier, then small pieces of reinforcement are welded to the body, and pieces of pipes of a suitable diameter are placed on them (the inner diameter of the pipes is slightly larger than the outer reinforcement). You can do the opposite: weld pieces of pipes, and insert fittings.

Just keep in mind that with such legs it will be difficult to move it: the legs will fall out. To avoid this, cut the thread.

See below for a video example of making one of the homemade braziers from a propane cylinder.

With the onset of heat, we are increasingly visited by the thought: why not get out to the dacha to fry meat in nature? It’s good if you already have a stationary barbecue grill or you are able to purchase its portable version. But what about those who do not have such an opportunity? To make according to our instructions a brazier with your own hands from a gas cylinder.

Types of barbecues

Braziers, depending on the dimensions, are divided into 2 types:

- portable - compact designs that can be easily disassembled, folded and transported. To reduce their weight, such kebabs are made of thin metal. This is their plus, since they are mobile, but there is also a drawback here - thin metal quickly burns out;

- stationary - solid structures that are impossible or difficult to transport. They are made of stone, brick, thick metal and other heat-resistant materials.

We will tell you how to make a stationary do-it-yourself brazier from a gas cylinder. With proper skill, you only need a few hours.

Instructions for making a brazier from a gas cylinder

To make a brazier with your own hands, you will need:

- empty gas cylinder (don't have your own - buy online);

- Bulgarian;

- welding machine;

- 4 hinges (we suggest using window hinges);

- metal handle (suitable from an old iron, from a pan);

- metal sheet 1 mm thick;

- 2 corners 40 mm;

- reinforcement or corner, from which we will make legs (7 m);

- hose and water;

- chalk (marking).

1. Prepare the balloon for cutting. Open the faucet and release the remaining gas from it. To avoid poisoning, do it outdoors, away from fire, and try to stay away yourself. Pour water into the container through the hose - it will squeeze out the remaining gas from the inside, which can explode from a spark when cutting metal.

2. We apply the markup. For the center (reference point) we take the connecting welding seam. The balloon itself in a circle reaches 96 cm. We divide it into 4 equal parts, each 24 cm long.

Having measured 24 cm from the seam to the right, we draw a longitudinal straight line with chalk - this is the future border of the cut.

We also measure 24 cm from the connecting seam to the left and draw a parallel longitudinal segment. After counting 3 cm from the upper and lower circular welds, we put serifs with chalk. Measuring 8 cm from the top notch, mark with chalk the location of the holes for the skewers. If you did everything right, there should be 6 of them.

We measure 10 cm from the notched line to the left and draw a parallel straight line - there will be a lid.

3. Cut out the cover. Using a grinder, we cut a balloon filled with water. First, we make a cut along a line 10 cm from the notched segment. Having completed this operation, we weld the hinges, as shown in the photo.

Only after that we complete the cutting of the cover around the perimeter.

We open it and drain the water, the brazier with our own hands from the gas cylinder is half ready.

4. We make limiters for the lid. We take two 40's corners and cut out holders 3 cm wide. We attach to the body of the barbecue (see photo) and weld.

Now, when the lid opens, it will not fall back and fill up the structure. At the limiters, you can increase the size of the corner, then the lid will not lean back much, and you will not have to reach far behind it.

5. We weld the handle. You can choose the lid for its location, but then try to pick up a handle with heat-insulating material, otherwise it will heat up during the barbecue and you may burn yourself.

The second version of the handle will avoid accidental burns. It is enough to weld a metal rod 10 mm thick to the side of the cover.

6. Cut off the rims of the balloon. To make it easier, you can make a transverse incision.

7. We process the edges of the opening so that the lid does not fall inward. From a sheet of metal 1 mm thick, we cut out long strips (width 3 cm), the length of which should correspond to the size of the sides of the rectangular hole for the cover,

and weld them around the perimeter.

It should turn out like this:

You can take a break for a few minutes and watch a video on how to make a portable homemade brazier from a beer can and four screws:

8. Since we have grill for barbecue, make holes into which skewers will be inserted. According to the marks made earlier (serifs spaced at an 8-centimeter distance), we drill holes.

Having marked in the same way the plate located on the opposite side of the holes, we make slots in it where the skewers will be inserted.

9. We cut off and weld the upper hole where the faucet stood.

10. We make slots that provide access to oxygen. We turn the cylinder over with the welding seam up, step back from the seam 10 cm to the side round holes under the skewers and draw a longitudinal line.

We measure another 10 cm from it and draw the second one. We connect the resulting two lines with segments, placing them at a distance of 5 cm from each other. These will be the cutouts.

We apply the same pattern on the other side, there will also be slots.

We cut the gaps.

11. Finishing making the brazier with our own hands, we weld the legs to it. They can be made from corner

or fittings.

Choose the height according to your height. Do-it-yourself barbecue from a gas cylinder is ready. It remains to paint it, giving the final presentation and providing protection against corrosion.

How to paint a homemade brazier?

Barbecue for barbecue can be covered:

- heat-resistant organosilicon enamel, which can withstand temperatures up to 600 ° C;

- powder thermal paint. True, this method of corrosion protection is not applicable at home, since it requires firing in a furnace with a high temperature.

Another method of anti-corrosion treatment of the brazier is oxidation. It is also not easy to implement, but it is quite feasible.

First, it is necessary to treat the body of the brazier with 5% sulfuric acid, then boil it in a highly concentrated solution laundry soap, and then boil for one and a half hours in a solution of caustic sodium. Such homemade brazier won't rust for a long time.

No matter how high-quality the anti-corrosion coating is, we do not recommend testing its reliability by leaving the brazier in the snow and rain. The best place its installation is a canopy. With the onset of cold weather, it is better to transfer the structure to some room, for example, a garage or a barn.

And in conclusion, a few tips for proper frying on the grill:

- making a fire in it, conditionally divide inner part brazier for two zones. In one, where there is more heat, cook meat, in the second, where the temperature is lower, vegetables and fish;

- do not turn the skewers frequently. Normal roasting can be achieved by turning the meat only 2-3 times. The coals should be red with a gray coating of ash;

- do not bring the meat to charring: black plaque is a direct path to cancer. The other extreme - weak roasting - threatens the risk of infection with helminths;

- add flavor to products by throwing a few branches of fruit trees on the coals;

- when preparing a barbecue in rainy weather, do not even think about transferring a homemade barbecue to the room. Poor traction will lead to an increase in the concentration of carbon monoxide.

To avoid fire, place the barbecue grill away from flammable objects. Near the legs there should be no grass, branches and boards. Do not rush to throw away the ashes: it can smolder during the day, which means it can cause a fire.

If you prefer traditional rectangular braziers, you can watch a video tutorial on how to make them:

Take it, tell your friends!

Read also on our website.